Engineering Services

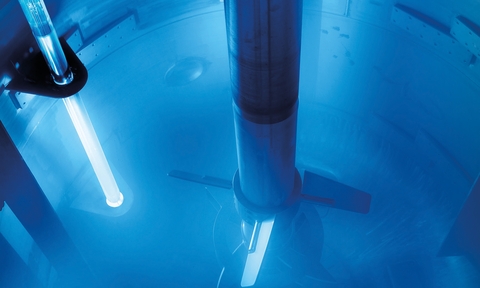

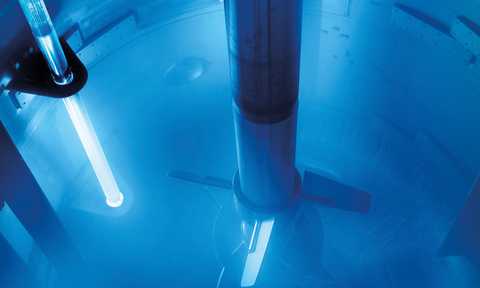

We offer targeted engineering services for the development, modification and redesign of customer specific non-standard photoreactors. This includes reactor optimization, modeling, thermal management, materials selection, and integration of light sources into ATEX-compliant or other regulated environments.

A core focus lies in the retrofitting and optimization of existing photoreactor systems, with the goal of significantly improving reaction selectivity, quantum efficiency, and overall productivity. Using advanced simulation tools, we identify process inefficiencies and develop tailored strategies for improvement – directly at the interface of light, reactor, and chemistry. We support plant operators seeking to increase the throughput and robustness of photochemical production, as well as OEM customers aiming to integrate cutting-edge photoreactor designs and light sources into their systems.

Take an overview of our services:

Peschl Consulting develops highly efficient, customized photoreactors that are specifically tailored to your application requirements. Through precise design and advanced development, we ensure maximum efficiency and scalability of your reactors.

- Development of customer-specific photoreactors (OEM)

- Design-in support

- Application-specific reactor design

- Custom PED / ASME pressure vessel design and validation

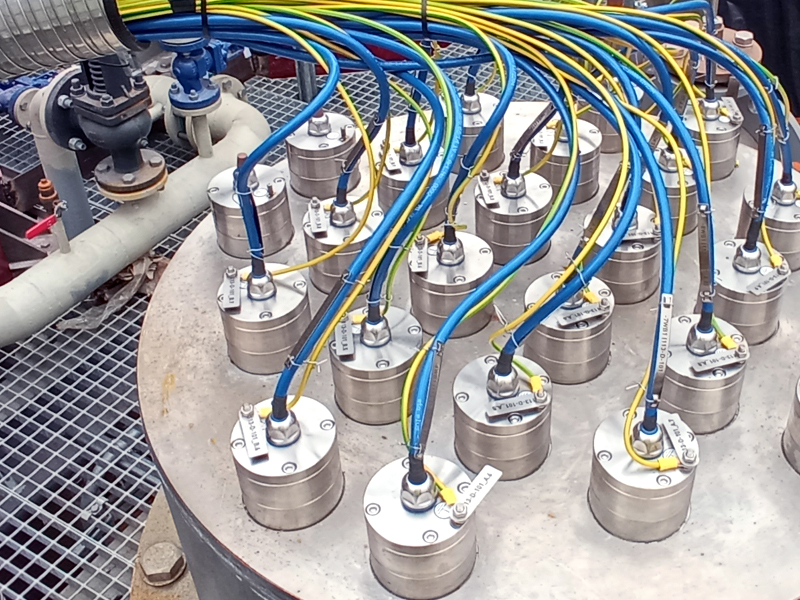

Custom UV modules – powerful, durable, and seamlessly integrable into your system architecture. We deliver solutions that meet the highest technical and regulatory standards – customized to your application and ready to integrate.

- Customized UVC Modules

- Complete Device Development

- System Integration & Support

- Compliance & Validation

Design and engineering of modular skid systems tailored to your process requirements. Whether for pilot plants, laboratory setups, or full-scale production, our skids are built for seamless integration, fast commissioning, and long-term reliability – all in compliance with applicable industry standards.

- Custom Engineering & Layout

- Fully Integrated Functional Units

- Regulatory Compliance & Documentation

Safety is our top priority. Risk Identification and Minimization in the Development and Operation Phase.Structured risk analysis based on DIN/EN ISO 12100 – forming a reliable foundation for safe machinery and plant design.

- Systematic Hazard Identification

- Documentation for CE Compliance

- Safety Concepts & Risk Reduction

Compliance with legal requirements is essential for market access. We offer compliance consulting for photonics, especially for products in the field of UV LEDs, laser technology and optical systems.

- Identification of relevant regulations (e.g. CE, RoHS, REACH, ISO standards)

- Advice on product certification of photonic devices

- Support with technical documentation and risk assessment